Belt conveyor safety operation

Were reviewed,

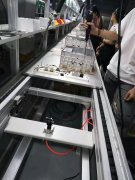

Belt conveyor has become one of the important equipment in the whole production process. Advanced structure, strong adaptability, small resistance, long service life, convenient maintenance and complete protection device is a significant characteristics of belt conveyor.

In front of the belt conveyor running, the first to confirm the belt conveyor equipment, personnel, goods are to be delivered in the condition of safety in good condition; Then inspect the normal movement part no foreign body, check all the electrical wiring is normal, normal to the belt conveyor in operation. Finally, check the power supply voltage and rated voltage of equipment difference not more than plus or minus 5%.

Second, the operation

1. Close the total power switch, check whether the equipment into the power supply is normal and the power indicator light is bright. The next step after normal operation.

2. Close the circuit of the power switch, check whether the normal. Under normal condition is: the equipment is not action, belt conveyor running light is not bright, inverter and other equipment of the power indicator light is lit, the inverter display panel display is normal (trouble-free code is shown).

3. According to the technological process, in turn, start the electrical equipment, an electrical equipment on the startup after normal (motor or other equipment has reached the normal speed, normal) to go to the next start of electrical equipment.

In the operation of the belt conveyor, must abide by the provisions of the items in the design of items to be delivered, comply with the design of the belt conveyor. Second, pay attention to all kinds of personnel shall not touch moving parts of belt conveyor, non-professional personnel shall not be arbitrarily contact electrical components, controls, etc. Finally, in the belt conveyor in the operation of the inverter can't level after the break, such as to determine the maintenance needs, you must can only be carried out under the condition of the stop frequency operation, otherwise may damage the inverter.

Belt conveyor running stop, press the stop button for system to stop all the rear can cut off the total power.

Three, model choice

(1) the weight of the delivery object (including spreader weight) size, shape and the hang way;

Line length and complexity, that is, how much horizontal rotary and vertical bending;

(3) environment, working conditions and work shift conveyor;

(4) conveyor speed and productivity;

5] special technological requirements.

Power roller by dynamic roll barrel component, next to the aluminum plate, sheet, rod, socket, drive, and a chain. Unpowered roller by unpowered roller barrel component, next to the aluminum plate, sheet, tie rod, socket. Power roller processing by the driver to drive traction chain, the chain turns the power on the roll barrel sprocket, thus by the rotation of work. Unpowered roller push-pull work-piece or extrusion artifacts by man, and on the roller of free movement.

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01