Product

News

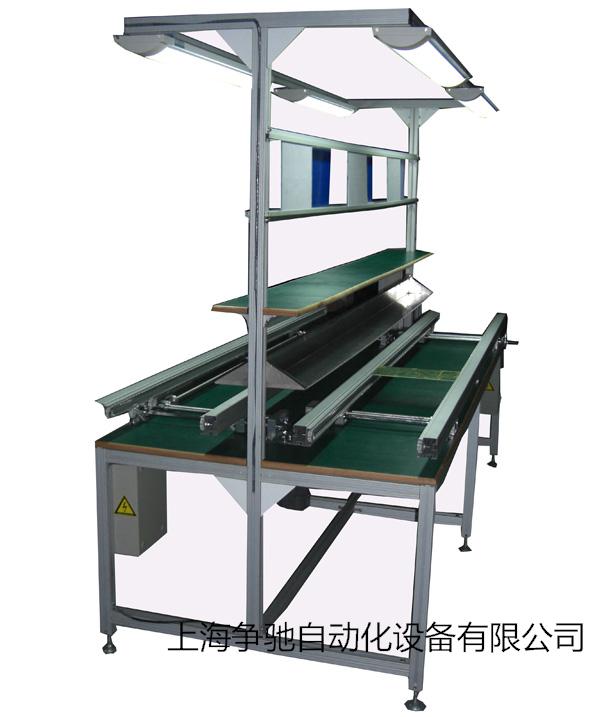

Heavy Shelves

Heavy shelves

Article source:http://www.zhengchiyw.com Release time:2016-02-23 15:33 Browse times:

Heavy shelf

Also known as the crossbeam type goods shelves, or the cargo shelf, belonging to the tray shelf, in the storage shelves system is the most common form a shelf. The whole assembly structure of beam column piece + form structure, concise and effective. According to the characteristics of the storage unit container equipment installation such as: every file, steel plate (laminated wood), a wire mesh layer, warehousing cage guide, drum rack etc. functional accessory. To meet the different forms of the goods storage unit container equipment.

According to the warehouse roof along the highly effective and forklift fork of maximum high determine shelf heights must first container unit of work is goods packing and weight and other characteristics were set, tray to determine the type, specification, size, and single supporting load and high stack (single supporting the weight of the goods general less than 2000kg), and thus determine the shelf unit span, depth, and the distance between layers. Shelf unit span is general in less than 4m, depth is less than 1.5m, low and high warehouse shelves height in the 12m or less, ultra high warehouse shelves height in general less than 30m (such warehouses are basically for automated warehouse shelf, total height is composed of some 12m within the column).

Such warehouse, low, high warehouse is mostly used forward type battery forklift, counterbalanced forklift truck, three to the forklift to access and shelf shorter also available electric pile high machine, ultra high warehouse stacker for access. High utilization rate of the space shelf system, flexible and convenient access, computer management and control, and can meet the basic requirements of modern logistics system.

Widely used in manufacturing industry, the third party logistics and distribution center and other fields, is suitable for many varieties of small batch of goods, but also suitable for few varieties and large quantities of goods. These shelves in the high and super high warehouse warehouse (mostly used in automatic warehouse shelves are mostly used such shelves).

The main features of heavy shelves:

In the general cargo through the tray, storage cage unit container equipment are deposited after the shelf storage.

D is the most common and widely used one of the shelves, suitable for the vast majority of warehouse goods or products using.

The goods arbitrarily chosen characteristics - 100%. Handling machinery such as forklift can arrive at an arbitrary location for storage, storage and convenient operation, quick!

- mechanical handling equipment for storage.

Heavy shelf structure

Heavy shelves by columns, beams, transverse bracing, bracing and self-locking bolt assembly, can effectively prevent the loosening of the bolts caused shelf instability; the crossbeam adopt special cold rolling P type closed beam; the structure is simple and reliable, light weight, bearing capacity and low cost characteristics of; column card and column connection with special design the safety pin, you can ensure that the beam impacted by external force and will not fall off; laminates using the strip plate, with bearing capacity is strong, wear-resistant, replacement simple, low maintenance cost.

Heavy shelves use

Heavy shelf has the advantages of low cost, safe and reliable, assembly and disassembly are convenient and simple; for in artificial access, each layer of the standard effective bearing over 800kg. Suitable for manual access box of goods, or and parts box, turnover box supporting loading scattered heavy goods.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products