Product

News

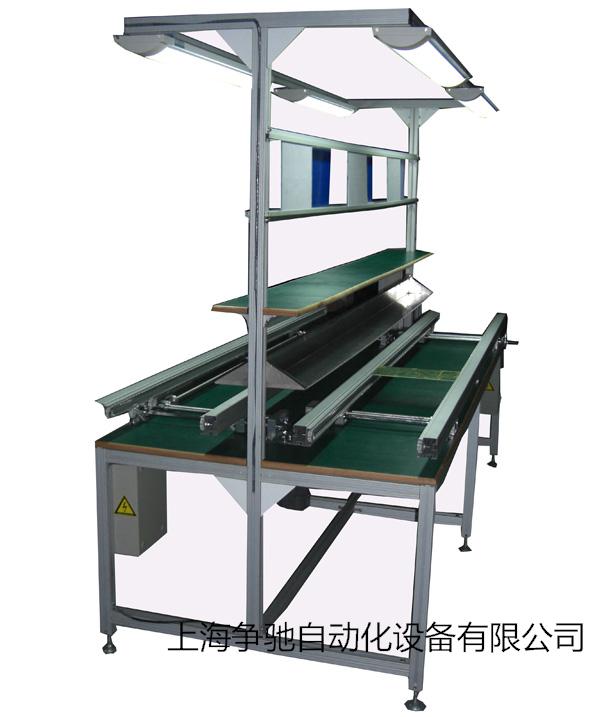

Flow Rack

Corton Flow

Article source:http://www.zhengchiyw.com Release time:2016-02-23 15:19 Browse times:

Fluent rack generally by medium-sized rack beams evolution and, through the raceway the goods from the picking end transported to pick up the end of the goods with the help of gravity gliding automatically, can achieve "advanced first in first out" operation, using low cost, storage speed, density of large. Roller type Aluminum Alloy or sheet metal is arranged between the shelves on each floor and beams flow, a certain slope (3 degrees) placed. General cargo for paper packaging or put the goods on the molecular compound plastic turnover box, using its deadweight cargo flow and advanced first out goods by car transport, artificial access, easy to access, shelf unit with each layer load in 1000kg, shelf height less than 2.5 meters. Picking and other places for the assembly line on both sides of the process of transformation, the core distribution, information management can be matched with the electronic label goods. Widely used in supermarkets, medicine, chemical industry and electronic industry.

Fluent rack: main device fluent rack covers shelf, raceway. According to the weight bearing raceway and supporting beam quantity adjustment.

The details are as follows:

1, each layer of adjustable spacing for a 50mm, can also be fine tuned by hanging;

2, the recommended minimum spacing selection of goods (Zhou Zhuanxiang) height +200mm, also can be adjusted according to the need of the integer 50mm;

3 fluent, according to L N and the number of turnover box is determined, fluent length is N*L+100mm;

4, the tilt angle can be adjusted, the standard is 3 degrees;

5, fluent in a form of D13, D28, D28F (flange);

6, shelf finishing: hot curing powder coating, the standard color is sky blue, can also be based on customer demand color selection;

7, can be designed according to customer requirements;

Width according to the appearance and the size of the customer turnover box length (d) x width (W) x height (H) to determine the width = slideway x (W + 50) + 20 + column, per unit total load is less than or equal to 1000 kg.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products