Product

News

Vertical Elevator

Vertical vibration hoist

Article source:http://www.zhengchiyw.com Release time:2016-02-23 13:52 Browse times:

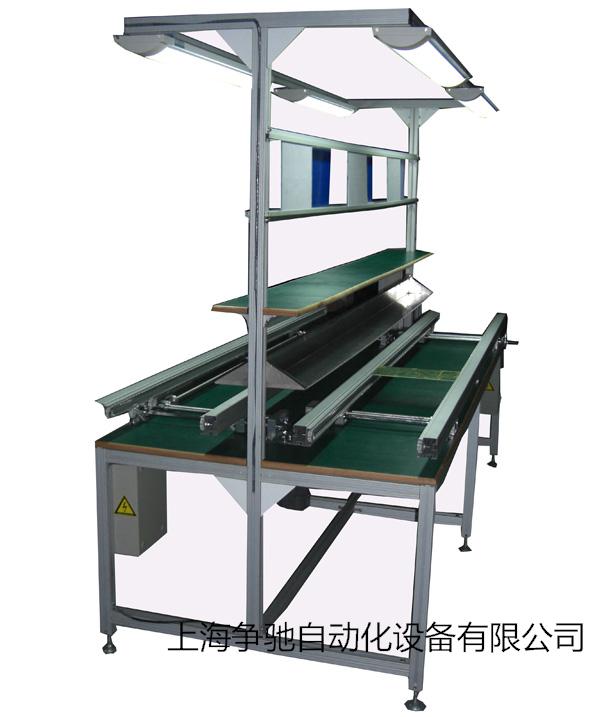

Product description:

The vertical vibration hoist is widely used in chemical industry, rubber, plastics, medicine, light industry, food, metallurgy, building materials, mining, food and other industries. The vertical vibration of elevator vibration motor as vibration source, using the two vibration motor amplitude, the material along the spiral conveying trough upward transport. Vertical vibration hoist is mainly used to enhance granular, powder and bulk materials. The conveyor has the advantages of simple structure, easy maintenance, quantitative material sending, delivery volume continuously adjustable, as the industry, small particles in the vertical transportation. In addition to having to lift the material from the bottom up, but also the complete drying of the material, the cooling effect. Separate trough, closed two structure, and according to different process requirements, selection of hoisting machine and the design of explosive material hoist design material particle classification.

characteristic

1 covers an area of small, simple and reasonable structure.

2 small power consumption, no noise, convenient maintenance.

3 closed to enhance the effective prevention of dust and harmful gas pollution in the work environment.

working principle

Vertical hoist motor vibration is composed of a lifting groove, vibration motor, vibration damping system and the base. The series of lifting machine is using vibration motor as vibration source, fixed in ascension groove on the two models of the same vibration motor center line cross angle installation and in the opposite direction from the synchronous rotation, vibration motor with eccentric block rotates in each instantaneous position generated by centrifugal force along the casting direction for reciprocating motion, the support on the shock absorber of the entire organism oscillate, make the material rising in the groove to be thrown up at the same time to move on, the material falls into the feeding groove, and is beginning to be thrown. This can be make the material fully contact with air, can also play a role in the cooling. The solid material of powder, bulk and short fibrous (except for the hoist with viscous and easy to agglomerate) can be vertical transportation, can also complete the drying and cooling effects on materials. Open and closed two structures. And can be designed according to user needs.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products