Product

News

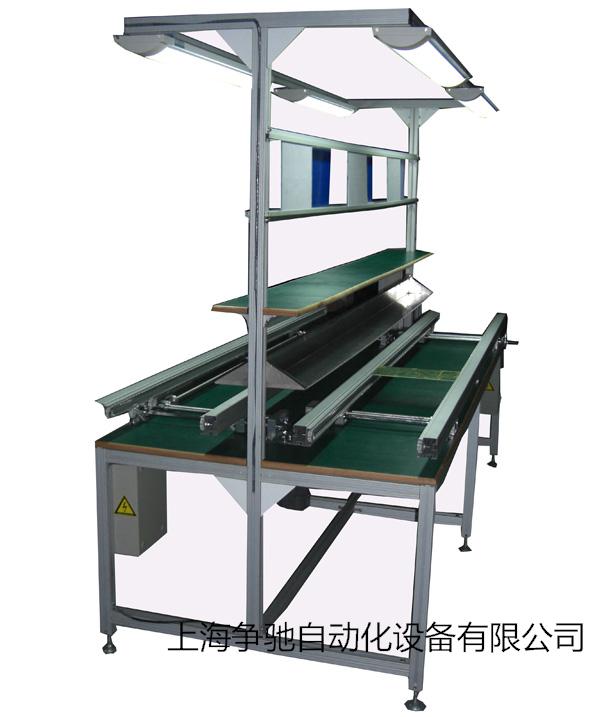

Cross Sorting Line

Cross type sorting conveyor line

Article source:http://www.zhengchiyw.com Release time:2016-02-23 13:22 Browse times:

Product description:

The cross sorting conveyor has a route flexibility, make full use of the space characteristics, can also be used to turn conveyor uphill / downhill. The merger of machine and can be used to configure and optimize a variety of methods, to improve system performance. Use the appropriate layout, only one system can establish multiple sorting machine area.

Sorting conveyor is used to complete the sorting and transporting products and the transportation equipment. Automatic sorting system generally consists of automatic control and computer management system, automatic identification device and classification mechanism, the main conveying device, pretreatment equipment and sorting crossing.

Automatic sorting system generally consists of automatic control and computer management system, automatic identification device and classification mechanism, the main conveying device, pretreatment equipment and sorting crossing.

1 automatic control and computer management system is to control the entire automatic sorting and command center, all the action of each department of the sorting system are decided by the control system. Its role is to identify, receiving and processing sorting signal, according to the sorting signal indicating the classification mechanism according to certain rules (such as variety, location etc.) for automatic classification of products, so as to determine the flow of products. Sorting signal source by scanning the bar code, color coded scanning, keyboard input, quality detection, speech recognition height detection and shape recognition, and so on acquisition, information processing and converted into corresponding picking orders, single or electronic picking signal storage, automatic sorting operations.

2 automatic identification device is the material can realize the automatic sorting system based. In the logistics distribution center, automatic identification system is the widely used bar code system and radio frequency system. Photoelectric scanning of bar code automatic identification system installed in different locations in the sorting machine, when the material in the visible range scanner, automatic reading of the bar code information material, through the software code can be translated into the bar code represents the material information, also perceived material in sorting machine upper position information, these information automatically transmitted to computer management system of the background.

3 classification mechanism refers to the automatic recognition of the material into the sorting machine main transmission line, and then through the classification mechanism to the diversion of materials to the designated position. The classification mechanism is the core equipment of the sorting system.

4. The main conveying device is the material is conveyed to the corresponding sorting crossing, for subsequent operations, consists of various types of conveying machinery into, also known as the main conveyor line.

5 pretreatment equipment is delivered to the main sorting sorting system of material conveying device of feed table and other auxiliary transport and operation etc.. Feed table has two functions, a is operating personnel use input device sorting materials for each destination address into the sorting system, as the material sorting operation instruction; second is to control the material sorting into the time and speed of the main conveyer, ensure the accurate sorting of classification mechanism.

6 sorting conveyor line is also called crossing shunt, the material from the main conveyor line to enter the corresponding set of goods aisle. General by the steel belt, conveyor belt, roller components slide, so that the material from the conveying device from sliding into the buffering workbench and putaway operations or Peihuo work.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products