Product

News

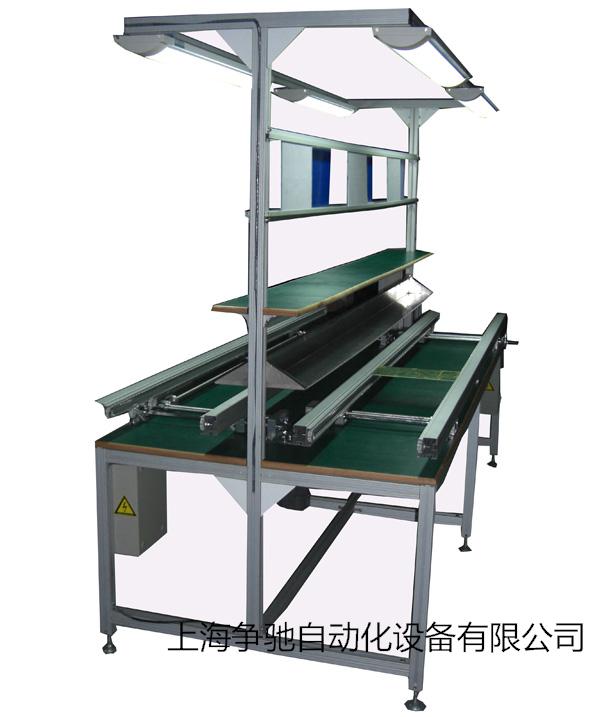

Vertical Sorting Transmission

Logistics vertical sorting conveyor line

Article source:http://www.zhengchiyw.com Release time:2016-02-23 13:31 Browse times:

Product description:

The vertical sorting conveyor feeding conveyor are usually placed in front of the actual sorting machine from the product of a simple conveyor belt start. The operator can be manual goods transported into the product of a discharge conveyor - ideal solution for high performance, human engineering.

1, the structure and the working principle of: product put by accumulating roller roller, aluminum side panels, sheet frame, a pull rod, a bearing seat, a driving device and a chain, wherein product discharge roller by a chain compression spring, transmits torque through friction, drives the roller to rotate. When the work is blocked, the roller is rotating, the friction plate sliding, realize product release function.

2, drive roller by the power roller barrel assembly, aluminum side panels, frame, rod, bearing seat, driving device and a chain. No power roller by unpowered roller components, aluminum side panels, frame, bearing seat, pull rod. Drive roller by the driving device to drive the traction chain, chain drive chain wheel of the power and the barrel rotation, and by rotation of the conveyor work. No power roller by sliding a workpiece or a workpiece extrusion workpiece, move in freely on the roller.

3, roller conveyor for to all types of boxes, bags, trays and other pieces of cargo transport, bulk materials, small items or irregular items need to be placed in the tray or container for conveying. Capable of transporting the weight of a large piece of material, or to bear a larger impact load, is easy to connect the filter between the drum line, can be used a number of drum lines and other conveyors or plane composition complex logistics delivery system, multi process. Stacking rollers can be used to achieve material accumulation conveyor. The roller conveyor has the advantages of simple structure, high reliability, convenient use and maintenance.

4, applicable to all types of boxes, bags, trays and other pieces of cargo transport, bulk materials, small items or irregular items need to be placed in the tray or container for conveying. To transfer the weight of a large piece of material, or to bear a larger impact load.

5, according to the structure form: driving roller can be divided into power lines and no power roller line, according to the layout of the form can be divided into the level of roller conveyor line, inclined roller conveyor line and turning drum line. Can also be specially designed according to customer requirements, to meet various customer requirements. The standard gauge drum line is within the width of 200, 300, 400, 500, 1200mm. Customer needs can also be used in other special specifications. Turning drum line standard within a radius of turn 600, 900 and 1200mm, can also be used in other special specifications according to customer demand. The straight section of the drum drum diameter of 38, 50, 60, 76, 89mm.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products