Product

News

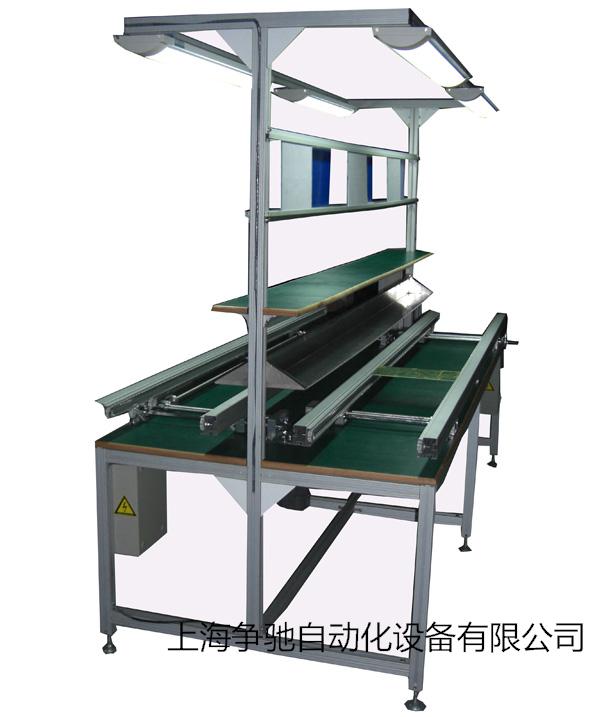

Plug Line Transfer Line

Plug line transmission line

Article source:http://www.zhengchiyw.com Release time:2016-02-23 11:04 Browse times:

Technical parameters:

The plug-in line is mainly used in electronic products, there are some applications to other products. Plug line conveyor in electronic factory are generally used for automatic insertion of substrate production, suitable for circuit board plug-in, welding, inspection and other production processes. Width adjustment device plug-in line conveyor using ball bearing international advanced, lightweight, flexible, no noise. A plug-in line conveyor mainly adopts aluminum structure, beautiful appearance, convenient installation.

Plug-in line, mainly in the form of: one-sided plug-in conveyor, bilateral type plug-in conveyor, straight line type plug-in conveyor, circular plug-in conveyor, inclined plane type plug-in conveyor, rotation shift load type plug-in conveyor.

On a single line of plug-in body length is usually: 2 meters, 2.4 meters, 3 meters, 3.8 meters, 4 meters, the height of the line is generally: 750mm (SIT), 1000-1100mm Rupa (standing). The plug-in conveyor each line body can be lengthened and the end of the turn, configuration of transplanting mechanism can be reversed and the connection body.

The motor power is usually a single plug-in line are: 40W, 60W, 90W. The use of power in the transmission speed of 0.5-3 M / min adjustable: 220V 50HZ.

The plug-in line used alone or with very good can improve production efficiency when using wave soldering machine, the main production line equipment is often used in some electronic factory.

Related news

- 皮带输送机撕裂故障及其防护措施分析2018-11-15

- 滚筒输送机的发展及现状研究(二)2018-11-15

- 滚筒输送机的发展及现状研究(一)2018-11-15

- 皮带输送机固体物料称重给料系统设计初探2018-11-01

- 摩擦式积放滚筒输送机装置的设计2018-11-01

- 滚筒输送机PLC控制技术在空调生产系统中的应用2018-11-01

Related products